How to Choose the Right Robot

In modern manufacturing, the importance of robots cannot be overstated. Their flexible operational capabilities and high precision make them crucial tools for enhancing production efficiency and reducing costs. The application of automation technology becomes particularly crucial in the face of an increasingly competitive market environment. The introduction of robots not only brings efficiency and accuracy to production lines but, more importantly, it allows people to focus more on creative and meaningful tasks.

When selecting the right robot, businesses must consider the characteristics and requirements of the production process, including product weight, size, and production speed. Carefully choosing a suitable robot can enhance production efficiency, reduce waste and energy consumption, and achieve long-term cost savings.

Moreover, the presence of robots is not meant to replace humans but to assist them in achieving automation, thereby unlocking human potential and creativity. This innovation not only improves production efficiency but also enhances job satisfaction among workers, creating a more positive and proactive work environment.

Key Considerations:

1. Consider Workload:

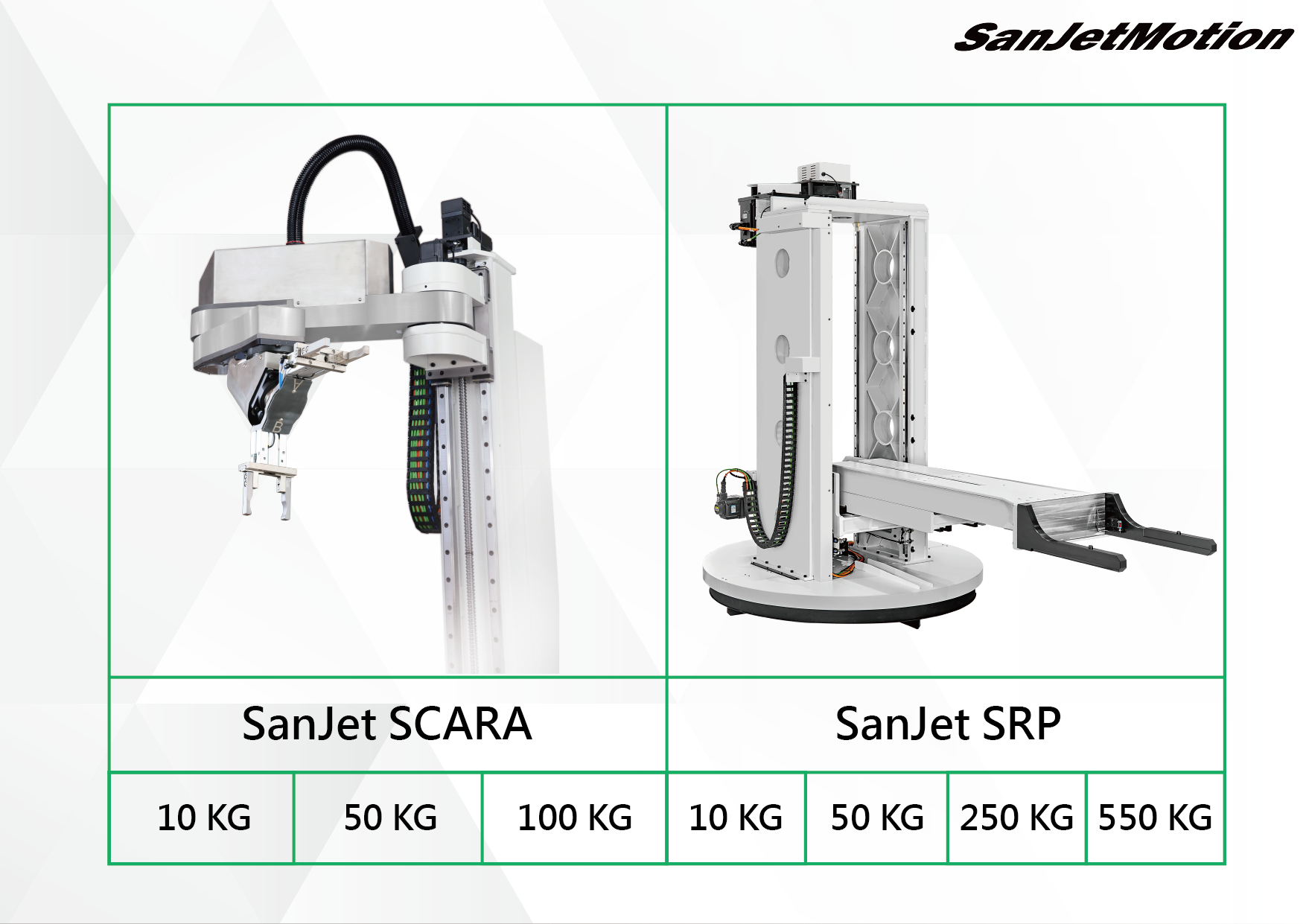

- Choose a robot based on product weight and size. SCARA robots are suitable for lighter products, while SRP SanJet three-axis robots with material storage are suitable for heavier materials.

2. Consider Material Gripping Frequency and Speed:

- Select a robot based on the speed and efficiency requirements of the production line. If frequent material changes are needed, SCARA robots are more suitable; if the change frequency is lower, SRP SanJet three-axis robots with material storage are a good choice.

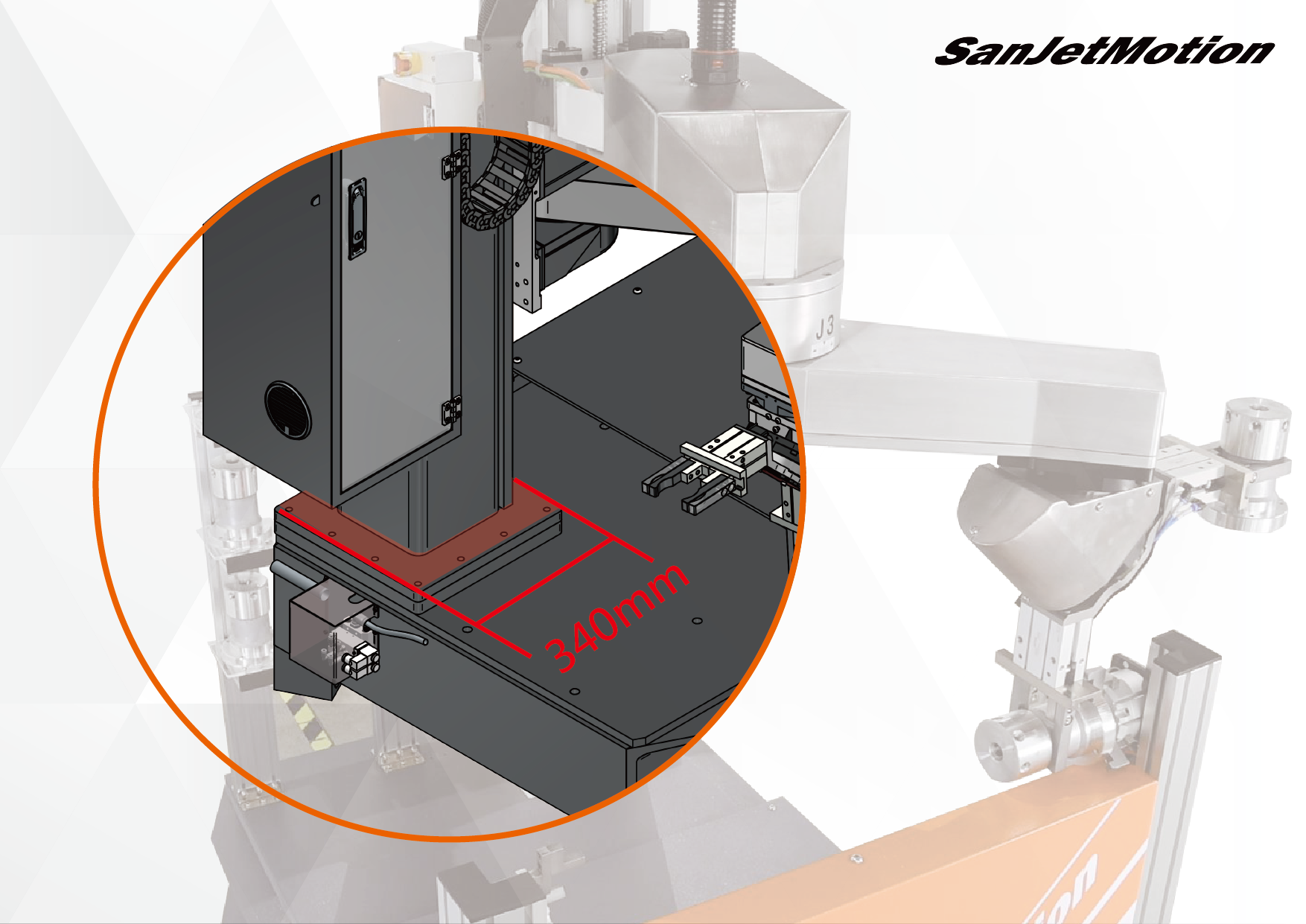

3. Consider Space Constraints:

- For limited production environments, choosing a robot with a smaller footprint helps save space and improve production line efficiency. SCARA robots have a relatively small footprint, making them a good choice.

4.Consider Material Handling Routes:

-When integrating robots with machine cover storage, careful consideration of on-site configuration is essential. Choosing SRP three-axis robot storage systems is recommended for direct linear path material handling from the front or side door of the machine. If space is limited, and material handling needs to be done from the side, SCARA robots offer more flexibility. This design ensures smooth and efficient operation of the production line while maximizing the flexibility of robot operation.

_工作區域 1-08.png)

Through these key considerations, businesses can choose the most suitable robot for their production needs, thereby enhancing production efficiency and achieving long-term stability and development.

SANJET Robot Specifications Comparison

_工作區域 1-04.png)

_工作區域 1-05.png)

Applications of Robotics

_工作區域 1-07.png)

< Tool Exchange for Milling Machine / Precision Automated Storage / Precision Automated Tool Magazine >

In conclusion, when choosing a robot, carefully consider factors such as workload, operating speed, and space limitations to ensure your choice aligns with the needs of the production line, leading to improved production efficiency and reduced production costs.

SanJet provides comprehensive pre-sales technical support and after-sales services. We offer customized support to ensure timely and effective assistance for customers in robot selection and usage. Our goal is to ensure that customers can rely on our products and services, ensuring the continuous and efficient operation of their production lines. If you have any questions, feel free to contact our professional team, and we will be happy to assist you.